|

| Plant Maintenance Resource Center

How Unbalance Affects Bearing Life

| |

|

|

|

|

|

How Unbalance Affects Bearing LifeBy Ahmed M. Al-Abdan, Maintenance Engr, GED/MD

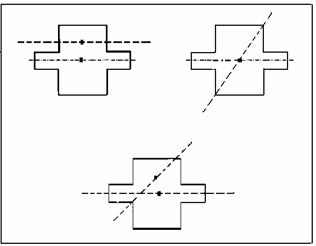

Mass unbalance in a rotating system often produces excessive synchronous forces that reduce the life span of various mechanical elements. First of all we will define unbalance case. Unbalance is basically very simple case caused by an asymmetry in the rotating element that results in an offset between the shaft centerline and center of mass (see Figure 1). Asymmetry can be an off-center weight distribution, or it can be a thermal mechanism that produces uneven heating and bowing of the rotor, or it can be an electrical effect that produces uneven magnetic field. There are many purposes of balancing done to a rotating element. One of that purposes is to reduce the force at the bearings. To eliminate the mass unbalance we have to requalize mass distribution of rotating element around it's centerline by using add or remove weights from available planes, which will reduce the centrifugal force at the bearings. This can be seen from the following formula:

Where:

For example, if an unbalance weight of 1.25 ounces is added to a rotor at a 6 inch radius, the resulting force for a rotor turning at 2000 rpm.

An important question to consider is how does this extra 53.1 pounds of force from unbalance affect the life of the bearing? To answer this question, we should define a problem can affect the life of bearings which called fatigue life, many of bearing manufacturer introduce their way to calculate fatigue life i.e. skf by using the following formula.

Where

The calculated L10 life is 101000 hours or about 11.5 years. If the additional unbalance load of 53 pound is added to the radial load (p) of 395 pounds the calculated L10 is reduced to 69253 hours or 7.9 years. The additional 53 pounds of force due to unbalance reduce life by 30%.

Copyright 1996-2009, The Plant Maintenance Resource Center . All Rights Reserved.

|