|

| Plant Maintenance Resource Center

A New Code of Practice for Remote Field Testing (RFT)

| |

|

|

|

|

|

A New Code of Practice for Remote Field Testing (RFT)Courtesy of : R.T.Co. - "a RUSSELL COMPANY"

As world leaders in RFT (Remote Field Testing), R.T.Co. is spearheading the initiative to create codes of practice that will help improve the quality of RFT services industry-wide. A new ASTM standard practice for RFT-for which R.T.Co. were primary authors-is due out soon. Watch for some positive changes in the RFT industry when the new standard comes into general use. BackgroundRFT is an electromagnetic method used to examine tubes such as those commonly found in boilers and heat exchangers. Use of RFT has been expanding during the last decade, helping to improve efficiency in heavy industries such as power, petrochemical, and oil and gas. In this competitive climate, companies seeking RFT services face an increasingly difficult task finding and evaluating vendors. There is a potential for confusion due to the lack of codes of practice. Right now anyone can purchase an instrument and offer services, whether they have had ten years or ten minutes experience. A single vendor carrying out poor quality work can affect the reputation of a technology across the continent, no matter how much good work is being done elsewhere. A standard practice is urgently needed. A New Standard Practice for RFTR.T.Co. is proud to have started and led the initiative to create a standard practice for RFT. The standard is being developed through ASTM (American Society for Testing and Materials), one of the world's best known forums for the development of standards. The standard practice is entitled In Situ Examination of Ferromagnetic Heat Exchanger Tubes Using Remote Field Testing. The main features are:

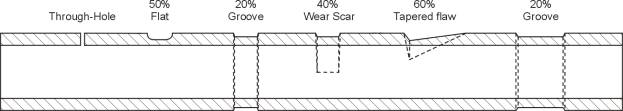

Preview of the proposed RFT system reference tube:

How the standard was developedThe major producers, consumers, researchers, and consultants in North American RFT were first brought together in the same room at an October 1998 symposium in Nashville. Sponsors were R.T.Co. (organizers), ASNT and EPRI. An RFT industry group was formed to create codes of practice and personnel qualification for RFT. The first task we decided on was to make a standard practice through ASTM, which we hope will lead to other guidelines and practices under ASNT, CSNDT (The Canadian Society for Nondestructive Testing), ASME (the American Society of Mechanical Engineers), and ISO (International Organisation for Standardization) In early 1999, the draft standard practice was authored at R.T.Co. and was sent out to RFT group members for comment. Over the course of 1999, the draft was simplified and improved through the hard work and commitment of the RFT group members. Those of us who worked through the standard line by line in the discussion meetings learned that an excruciating attention to detail is often rewarded by a clearer and more useful standard. EPRI invested time and money into the creation of a test bundle which was circulated to several companies in Canada and the USA. The bundle was used to evaluate the current state of the art in RFT, and had a considerable effect on the accuracy and credibility of our work. When Will the New Standard be Available?The standard is now under review by members of ASTM's committee E07 on Nondestructive Testing, for discussion at their June 2000 meeting. If the standard meets with unanimous approval, it could be published this summer (2000). If there are persuasive negative ballots, amendments will be made for balloting in January 2001. Check the R.T.Co. web site for continuing updates. R.T.Co.'s Involvement with ASNT codesR.T.Co. also maintains an active involvement in the ASNT Electromagnetic Committee, which meets twice-yearly, at the ASNT Spring and Fall conferences, to develop codes of personnel qualification in electromagnetic methods of NDT. Would you like to be involved in RFT standards development?At the R.T.Co. head office in Edmonton, contact David Mackintosh or Jim Yukes, 780-468-6800. At the EPRI NDE Center, contact Larry Cagle, Project Manager and RFT Group Chairman, tel. 704-547-6171. Why get involved in the development of standards?

Selected References on RFT and Standards Development

R.T.Co.. - "a RUSSELL COMPANY"

Copyright © 2000 R.T.Co.. All rights reserved.

Copyright 1996-2009, The Plant Maintenance Resource Center . All Rights Reserved.

|