|

| Plant Maintenance Resource Center

Your Facility is Leaking-Get the Picture

| |

|

|

|

|

|

Your Facility is Leaking - Get the PictureAuthor : Gregory R. Stockton

Plant Maintenance Resource Center Home Maintenance Articles Aerial thermal mapping of your facility or complex every few years will reveal leaks in all types of systems, like steam and condensate return lines, hot water lines, chilled water lines, supply water mains, distribution pipes, storm water drains, building heat loss and moisture leaks into your roofs. Aerial photographs should be taken every few years as well. They are inexpensive and can be a great asset when discussing future building additions with management, planning utility repairs and improvements, drawing CADs of the facilities and for uses as simple and as handy, as 'showing' outside contractors where not to park. The methodology for taking infrared (IR) thermographs is similar in many ways to taking aerial photographs. To collect the data, the aircraft flies over a given area with a camera mounted to the airframe and oriented looking straight-down (NADIR) to the ground. Oblique or lower angle shots are taken out the side of the aircraft by pointing the camera at the desired angle. The imagery is stored on film or a computer hard drive and later copied it to a convenient deliverable, such as a DVD. Aerial photos are taken during the day, obviously, because the sun provides brilliant visible light so that the user can see features on the ground, like buildings, bridges, roads, etc. Where aerial infrared thermography differs from aerial visible photography is the time of day when the survey occurs and the wavelength of the imagery that the detector collects. IR thermography of ground objects is performed at night because the sun and its effects on objects is a distraction in the imagery. Thermography reveals sources of heat and the relative differences in heat from one object to another. Infrared imagery is a grayscale picture whose scales (or shades of gray) represent the differences in temperature and emissivity of objects in the image. Objects in the image that are lighter in color are warmer and darker objects are cooler. No object in an IR image is detected via visible light wavelengths (400-700 nanometers), rather only from thermal infrared wavelengths in the 3000-5000 nanometers or 8000-14000 nanometers range. Lights and other relatively hot objects are very evident, but as a result of their heat emissions, not their light emissions. Collected IR imagery may then be modified in a number of ways to enhance its value to the end user, such as digitally adjusting the imagery to find particular anomalies and zooming in on different areas of interest. These post-processed images can then be used to prepare predictive maintenance reports on the various systems. Thermal Mapping and Ortho-Rectification

In order to produce ortho-rectified thermal maps (see figure 1), the ultimate [most useful] product, much more information must be gathered and tagged to the IR imagery. During the flight, the aircraft flies straight, smooth lines on a pre-planned grid, allowing 25% side lap of the imagery. The IR operator manages the sensor data-acquisition (see figures 2, 3) following a structured checklist for orderly data file management. The imagery must be collected with a precise direct-digital timing system, a 3-axis ring-laser-gyro and an inertial navigation system (INS), which is tightly-coupled to a real-time differential GPS satellite positioning system that provides x, y, z positioning of the aircraft at all times. After imagery is collected and QC is verified, the digital infrared imagery is then processed into a series of ortho-rectified image tiles, which are stitched together to create a giant mosaic image. An on-board computer system puts all this information together using a digital elevation model (DEM) of the scene that consists of a uniform grid of point elevation values and the position and orientation of the camera with respect to a three-dimensional coordinate system. The result is presented as a high-resolution IR image in the form of a geo-TIFF, which is compatible with any GIS software such as ESRI ArcView, AutoCAD 3-D Map, Global Mapper, MapInfo, etc.

Applications for Thermal Mapping Steam and condensate return lines (see figure 4) are almost always readily visible with infrared imaging, even when no notable problems exist. This is due to the fact that no matter how good the insulation, there is always heat loss from the lines, which makes its way to the surface. Problem areas are generally quite evident, having brighter infrared signatures that exceed the norm. Steam line faults normally appear as an overheated line or as a large hotspot in the form of a bulge or balloon along the line. Overheated lines often occur when the steam line is located in a conduit or tunnel. If there is a leak in the line, it will heat up the conduit with escaping steam. If a steam line is buried directly in the ground with an insulating jacket, a leak will usually saturate the insulation, rendering it largely ineffective and will begin to transfer heat into the ground around the leak, producing the classic bulge or balloon-like hot area straddling the line. Some leaks may show up as an overheated manhole or vault cover. Manholes or vaults that contain leaking steam system control apparatus will often heat the covers to warmer than normal temperatures.

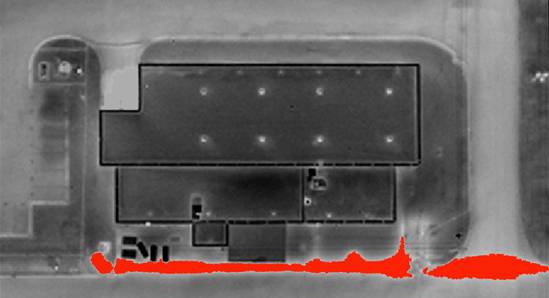

Figure 4) IR thermograph showing a leaking steam line (highlighted in red). A leaking sewer line or water main (see figure 5) may go undetected for years, especially if the leaking liquid is flowing into a storm drain or a stream that no one monitors. Leaking sewage collector lines, storm water drain discharges, water mains and taps into storm water drainage lines can often be identified by their thermal infrared signatures during cold times of the year. As these sources of waste or pollution leak, seep or empty into creeks, streams, rivers and lakes, their thermal signatures vary from their surroundings because the liquid from under the ground is relatively warm flowing across the ground and down a bank into a stream and because the warm plume of liquid joining and flowing downstream with the body of water are detectable due to the difference in temperatures of the two liquids. Late fall, winter and early spring are well suited to this type of inspection because of the cooler water temperatures (ground and surface waters) and because the interference to view by(delete by) foliage is minimized. Ground water seeps and outfalls of all types are also easily distinguishable for similar reasons.

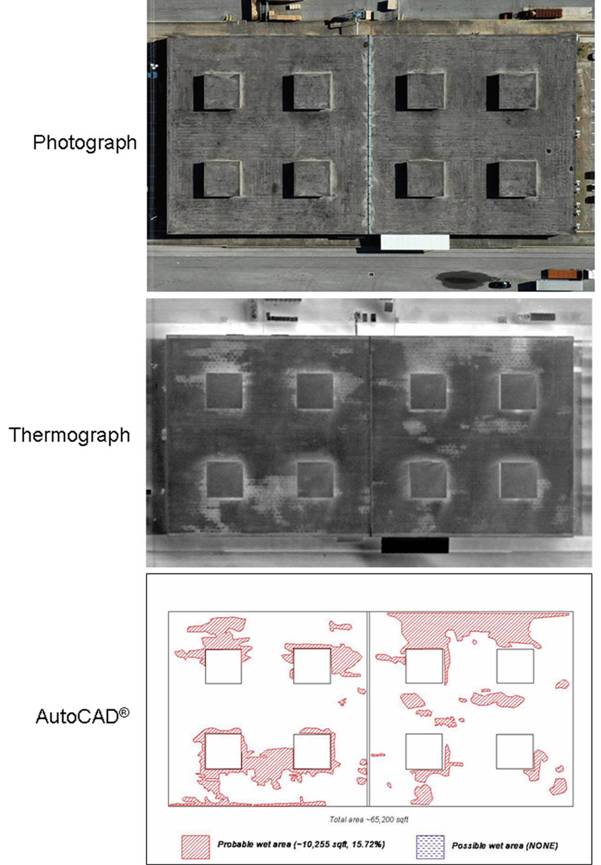

Figure 5) Thermograph of a storm drain (highlighted in red) leaking wastewater down to the bank of a creek and joining the flow. The leak is coming from the adjacent building. Roof moisture survey reports (see figure 6) are made by capturing IR and visual images and making scaled drawings of the wet areas, so that surgical repairs can be accomplished. Almost all roof insulation materials discarded in the US annually are dry. Why throw away 95% of the insulation when it is not damaged? With a thermal map of a group of buildings one can narrow down the roofs that have problems from the ones that do not on a wholesale basis. This allows the (delete the) facilities management to concentrate on those roofs that need to be repaired. Subsurface wet areas in a flat or low-sloped roof show up as lighter areas in the IR imagery at night because the latent heat (from daytime heating) in the trapped water mass is greater than in the dry, functioning insulation or roof substrate. Areas of roof moisture contamination can be nebulous in shape and sometimes mottled in appearance, although they are commonly found in linear or puddle-like shapes. The linear shapes many times follow low areas, drainage routes, roof edges and seams. Puddle-like round or oblong shapes often form around roof penetrations such as mechanical equipment, standpipes, vents and drains. After sunset when the entire roof structure cools down, wet areas of roof insulation and other materials continue to radiate heat because of their higher mass.

Figure 6, 7, 8) Photograph, thermograph and CAD drawing of a flat roof with moisture contamination. Advantages of Aerial IR Imaging of Roofs

With all the roofs surveyed and existing CAD drawings corrected, updated, saved and layered into a GIS or CAD system, the facilities operator takes control of all the roofs. Knowing the condition of all the roofs allows for better life-cycle preventive maintenance, warranty enforcement, budget planning and improved roof asset management. Conclusions: It is true that a picture is worth a thousand words; so get the big picture of your facilities and start speaking volumes about its condition. Author Biography:

Copyright 1996-2009, The Plant Maintenance Resource Center . All Rights Reserved.

|